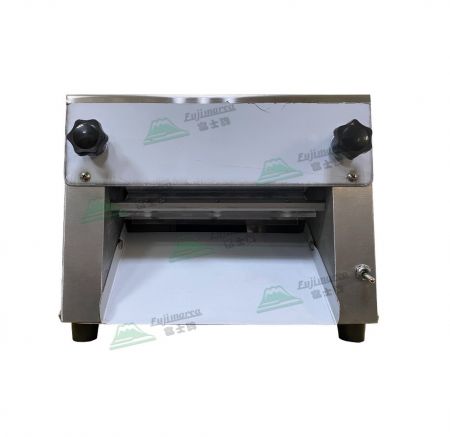

Electric Dumpling Wrapper Maker - Table Type

MC-508

Table Type Dumpling Machine

Electric Dumpling Wrapper Maker is a smaller model of Electric Dough Sheeter, which is designed for making sheets of the width in 5 - 10 cm. Used to make dumplings, wontons, and gyozas, etc.

Put small buns of dough into the machine technically, and make it into the round sheets. The adjust-space of rollers is 1 - 5 mm. The machine can effectively make the taste consistent, save the workforce, and enhance competitive advantage.

The dumpling Wrapper Maker has many advantages. First, the price is more economical and affordable than commercial type. Second, the size is delicate. It is only a half weight of Electric Dough Sheeter Machine, so it is suitable for homemade usage and diners. Third, we use valid and high-power motors, which are not easy to burn out under regular use.

How to operate?

After dividing dough into small buns, then start to roll it into circular wrappers.

1. Clean the roller by a few doughs before use. After running it 3 - 4 times, the surface will be clean up. Then, remove the contaminated.

2. Adjust the space of rollers by the knob to 3 mm. Roll the dough into shape oval. After that, adjust the space to smaller, and put the short side of sheets ahead to make the shape of circular.

3. After use, wipe the surface with a cleaning cloth.

Maintenance and Troubleshooting:

1. If the dough is too moist to sticky, you can remove it with a food scraper.

2. If the space is too thin, it makes the big-size dough into wavy. In addition, it affects the motor to be overheating and damage the gears.

3. The gears in the machine should add solid oil for maintenance regularly.

Features

1. For small doughs, the diameter of 4 - 5 cm. The pressing roller can adjust the thickness of 1 - 5 mm.

2. Compared to the commercial model, this type is smaller and lighter, which is more suitable for home use and diners.

3. The feeding plates and the entire cover are made of stainless steel 430#, which can solve the problem of mold growing caused by wood.

4. Pressing rollers are high quality with no coarse.

5. Follow the steps of feeding, you can make round wrappers very easy.

6. Using the machine instead of manmade is effectively and making the taste consistent.

Specification

● Power: Gear Motor 40W

● Voltage: 110V / 60Hz *

● Roller Width: 21cm

● Roller Width: 1 - 5mm

● Machine Size: 22 x 31 x 26 cm / 18 kg

● Packing Size: 24 x 33 x 31 cm / 21 kg

* Please tell us the voltage and plug you need.

- Related Products

Electric Dough Sheeter - Roller Type

MC-504

Roller type electric dough-pressing machine is designed for making sheets of dumplings, jiaozi,...

DetailsElectric Noodle Maker - Roller Type

MC-510

This model is for pressing doughs and making noodles, 2 in 1. The width of the rollers is 21 cm, which...

Details

Electric Dumpling Wrapper Maker - Table Type - CE Certified & Award Winning Design Fruit Juice Processing Machinery Manufacturer | JYU FONG MACHINERY CO., LTD.

Located in Taiwan since 1968, JYU FONG MACHINERY CO., LTD. has been a stainless steel food machines manufacturer. Our main food machines, including Electric Dumpling Wrapper Maker - Table Type, Electric Ice Shavers, Meat Grinders, Fruit Juicer Machines, Ginger Crushing Machines and Vegetable Cutting Machines, which have won the IPO design patent and CE certified.

Our staffs have rich experience. 70% of them have more than 18 years of experience and perfect cooperation among members. Besides the regular products, we pursue the new elements of machine to fit the market needs. We are specialized in ice shaver, meat grinder, kumquat & lemon crusher, vegetable dicer and stripper, bean grinder and rice grinder. All Jyu Fong food machines are 100% made in Taiwan, we take excellent technology at Electric and manual ice shaver, Electric meat grinder, Wheatgrass Masticating Juicer and so on. We do quality control at every step, so we bring you the best quality.

Fujimarca has been offering customers high-quality industrial food machines, both with advanced technology and 50 years of experience, Fujimarca ensures each customer's demands are met.